In 2005, with a renewed mandate and refocused organization, Hydro set strategic

goals to guide its business into the future. One of those goals highlights the

organization’s ongoing and continued commitment to environmental

responsibility.

Goal: To Be an Environmental Leader

As a company and a member of the community we have a belief and a

responsibility to protect the environment we live and work in. We will

strengthen our commitment to protecting the environment and will focus on

reducing emissions from our power generation activities. Our Environmental

Management System and ISO 14001 certification are key components of this

commitment and they will continue to be the cornerstone of our environmental

work.

Our structured and consistent management approach to dealing with environmental

issues facing Hydro has proven to be successful, and we have committed to

continue to build on the success achieved in 2005.

Our Environmental Management Systems (EMS) provide us with a solid framework

for environmental management and continual improvement. We are committed to

managing our operations to reduce our environmental impact, while balancing our

mandate to provide our customers with safe, reliable, least-cost power. All

Hydro divisions have been ISO 14001 certified since 2004, and this gives added

assurance to all our stakeholders of continued environmental excellence.

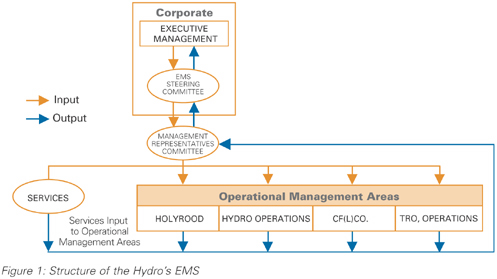

The six designated management areas (Figure 1) within Hydro manage their

environmental aspects through EMS’s consistent with ISO 14001. Each EMS is

certified and registered by a third party,

Quality Management Institute (QMI).

In 2005, Hydro continued to show improvements on our environmental Key

Performance Indicators, electronic EMS documentation and EMS surveillance

audits. General accomplishments resulting from the Environmental Management

Programs (EMP) in each of the Management Areas in 2005 are detailed in this

section.

The Corporate Management Area consists of the leadership team and a committee

of managers with responsibilities for facilities and operations with

environmental aspects. The goal of this Management Area is to co-ordinate the

development and maintenance of the overall EMS for Hydro and to identify

environmental aspects appropriate to the leadership team’s activities and

responsibilities. Although the operational and services EMS are managed

independently, a common and consistent Corporate Environmental Policy and

Guiding Principles sets the standard. Periodic reviews of activities and issues

are conducted to ensure consistency with corporate standards.

Two significant environmental aspects were identified in the Corporate

Management Area EMS review in 2005. These were:

-

communication of Hydro’s environmental policy and performance to relevant

stakeholders; and,

-

management of emerging and critical environmental issues.

Objectives, targets and programs were identified and pursued related to each of

these aspects. Some of the accomplishments included:

-

undertaking a process review of the Environmental Performance Report format and

production of the annual report in the format chosen;

-

production of a draft fact sheet related to the management of treated wood;

-

advertising Hydro’s environmental commitment and activities in external

publications;

-

preparation of the environmental section of Hydro’s Intranet site;

-

production of environmental articles in the Outlet, Hydro’s internal

newsletter; and

-

observance of Environment Week at Hydro Place, in St. John's.

As well, in 2005, Hydro’s Leadership Team and Board of Directors reviewed

options for managing air emission issues associated with the 490 MW Holyrood

Thermal Generating Station and approved a major initiative to improve the

quality of air emissions by reducing the specified maximum sulphur content of

the bunker “C” fuel burned at this facility from two per cent to one per cent.

This change is projected to reduce emissions of sulphur dioxide by 50 per cent

and emissions of particulate by 40 per cent. Also in 2005, Hydro tracked

federal government initiatives relating to emissions of greenhouse gases and

evaluated strategies for ensuring compliance.

Currently there are four groups within the Services Management Area that have

environmental aspects identified. These groups include: Systems Operations and

Customer Services, Engineering, Supply Chain Management and Environmental

Services.

In 2005, results included:

-

negotiation and finalization of the Diesel Generating Station Certificate of

Approval with the Department of Environment and Conservation;

-

2005 marked the first full year of production at the Ramea Wind-Diesel

Demonstration Project. Through the power purchase agreement with Frontier Power

Systems, Hydro purchased 418,000 kilowatt hours (kWh) of energy, offsetting

about 10 per cent of Ramea’s requirements in 2005 that would otherwise have

been supplied by diesel generation;

-

ongoing progress on a program managed by the TRO Engineering Department to

improve management of sulphur hexafluoride (SF6

a gas with significant greenhouse gas (GHG) potential, through education and

development of handling procedures designed to reduce the potential for

releases to the environment;

-

ongoing management of the impact of the Granite Canal Hydroelectric Generating

Station’s operations on fish habitat. This involves the development and

implementation of controls and procedures to coordinate the operation of the

generation facilities with the Fish Habitat Compensation Facility constructed

as part of this development; and

-

in 2005, Environmental Site Assessments were carried out on sites throughout

Hydro’s system including CF(L)Co. Eleven Phase I site assessments were

completed, nine Phase II ESA, complete with Risk-Based Corrective Action

(RBCA); and 10 RBCAs were undertaken based on Phase II ESAs completed during

previous years.

Thermal

The Holyrood Thermal Generating Station is a 490 MW plant located in Holyrood,

Conception Bay South. Holyrood’s EMS was initially registered in January 1999,

and obtained re-registrations in 2002 and 2005.

In 2005, Holyrood made progress on 13 EMPs, resulting in:

-

an improvement in efficiency of the conversion of fuel energy and associated

reduction in selected emissions intensities;

-

inspection and remediation of fuel containment equipment;

-

completion of a study on the control of regeneration wastes;

-

advancement of an emissions reduction strategy and approval to reduce fuel

sulfur content from two per cent to one per cent;

-

continued removal of PCB waste and asbestos from the plant; and

-

continued recycling of scrap metal.

Hydro Operations

The Bay D’Espoir Management Area consists of seven existing generating stations

on the island with an installed capacity of 604 MW.

In 2005, some of the results included:

-

as a way to minimize the risk associated with undergroun fuel storage systems,

three underground fuel systems were removed and replaced with above ground

double-walled fuel systems;

-

implementation of a new standard operating procedure for pressure testing of

fuel piping systems;

-

switch to environmentally friendly lubricants for Unit 7 at the Bay D’Espoir

Generating Station;

-

development and delivery of an Environmental Awareness Program to Hydro

generation employees; and a study of energy consumption at the Bay D’Espoir

site resulted in new procedures for conservation.

Churchill Falls

The Churchill Falls Hydroelectric Generating Station has an installed capacity

of 5,428 MW. Associated with this development is approximately 1,200 km of

high-voltage transmission lines, an airport and the Town of Churchill Falls.

Environmental aspects of these facilities are included in the EMS. The

environmental aspects of the decommissioned Twin Falls Hydroelectric Station

are also managed through CF(L)Co’s EMS. The EMS was registered in 2000 and

re-registered in 2003.

Some of the results of the 2005 EMPs were:

-

continued use of environmentally-friendly wicket gate grease and transformer

oil, with seven of 11 turbines and six of 11 transformers converted to

environmentally-friendly products to date;

-

a monitoring program to ensure ability to prioritize maintenance for turbine

units that experienced the highest oil losses. One turbine unit is repaired per

year;

-

conversion of two drainage sumps in the powerhouse into oil water separators;

-

training was completed by employees in the areas of environmental emergency

response planning, basic oil spill response, environmental awareness training,

and training by line crews related to the environmental protection plan for

transmission and distribution line maintenance;

-

a wind-blown debris fence installed at the town and plant landfill was

constructed 7.6 meters high and 120 meters long; and

-

a river oil response building was constructed near the tailrace.

Transmission and Rural Operations

The Transmission and Rural Operations (TRO) Division consists of three regions

that manage 23 rural, isolated diesel generating plants (30.2 MW), three gas

turbine plants (125 MW), and approximately 7,350 km of transmission and

distribution lines and associated switching stations. The three regions share a

common EMS. In 2005, Network Services was added to the EMS.

In 2005, significant accomplishments included:

-

updates to the five-year plan for improvements to prevent potential

environmental impacts from fuel storage systems;

-

updates to the five-year test plan for the reduction of PCBs to indicate

equipment to be tested;

-

a protocol for identification, removal and disposal of PCB contaminated

lighting ballasts;

-

continuation of a study for alternate forms of applications to reduce the use

of herbicides for vegetation control;

-

completed information collection related to environmental sensitivities for new

transmission and distribution lines in TRO Central, Northern and Labrador and

-

utilization of a software package to update and track treated-wood material removed from

service, recycled, reused, stored or disposed.

|