Newfoundland and Labrador Hydro Group of Companies will help sustain a diverse

and healthy environment for present and future Newfoundlanders and Labradorians

by maintaining a high standard of environmental responsibility and performance

through the implementation of a comprehensive environmental management system.

The following guiding principles set out the Hydro Group's environmental

responsibility:

-

implement reasonable actions for prevention of pollution of air, water, and

soil and minimize the impact of any pollution which is accidental or

unavoidable;

-

use energy as efficiently as possible during the generation, transmission, and

distribution of electricity, and the operation of its facilities, and promote

efficient use of electricity by customers;

-

maintain a state of preparedness in order to respond quickly and effectively to

environmental emergencies;

-

recover, reduce, reuse and recycle waste materials whenever feasible;

-

use the Province's natural resources in a wise and efficient manner;

-

audit facilities to assess potential environmental risks and continually

improve environmental performance;

-

integrate environmental considerations into decision-making processes at all

levels;

-

empower employees to be responsible for the environmental aspects of their jobs

and ensure that they have the skills and knowledge necessary to conduct their

work in an environmentally responsible manner;

-

periodically report to the Board of Directors, Executive Management, employees,

government agencies, and the general public which we serve on environmental

performance, commitments and activities;

-

comply with all applicable environmental laws and regulations, and participate

in the Canadian Electricity Association's Environmental Commitment and

Responsibility Program;

-

monitor compliance with environmental laws and regulations, and quantify

predicted environmental impacts of selected activities on the environment;

-

respect the cultural heritage of the people of the Province and strive to

minimize the potential impact of Corporate activities on heritage resources.

|

Newfoundland and Labrador Hydro (Hydro) is a Crown Corporation,

owned by the of Newfoundland and Labrador. Hydro is the parent company of the

Hydro Group of Companies (Hydro Group) comprised of Newfoundland and Labrador

Hydro, Churchill Falls (Labrador) Corporation Limited (CF(L)Co), Lower

Churchill Development Corporation Limited (LCDC), Gull Island Power Company

Limited (GIPCo), and Twin Falls Power Corporation Limited (TwinCo).

The Hydro Group's installed generating capacity of 7,288 megawatts (MW) makes it the

fourth largest of all power utilities in Canada. Its power generating assets

include the Churchill Falls Generating Station which is one of the largest

underground powerhouses in the world with a rated capacity of 5,428 MW, one

oil-fired plant, four gas turbines, 26 diesel plants and, including Churchill

Falls, 10 operating hydroelectric plants.

With a dedicated workforce of 1,144 full-time equivalent employees, Hydro is

the Province’s main energy provider with electrical sales of 39,181 gigawatt

hours (GWh) in 2005; 9,011 GWh for domestic use and 30,170 GWh for export. The

company also maintains over 4,780 km of transmission lines.

Hydro continues to be focused on delivering safe, reliable, least-cost power in

an environmentally responsible manner to residents, businesses and industrial

customers in Newfoundland and Labrador. In 2005, our shareholder, the Province

of Newfoundland and Labrador, gave Hydro an expanded mandate to grow our

business and to pursue new energy opportunities. With our shareholder and Board

of Directors aligned on strategic goals, the company restructured to pursue

opportunities in Labrador hydro developments, alternative energy, and oil and

gas, while still maintaining a strong focus on its core business, providing

least-cost power to Newfoundlanders and Labradorians.

There are currently four distinct business areas within Hydro: Regulated

Operations; Churchill Falls Operations; Lower Churchill Development Project;

and Business Development. The potential of each is fueled by vision and energy.

|

June 4 to 10, 2006, marks the start of Environment Week, and at Hydro we are

proud to highlight our accomplishments and focus on our environmental efforts

through the release of our annual Environmental Performance Report

and other Environment Week activities.

June 4 to 10, 2006, marks the start of Environment Week, and at Hydro we are

proud to highlight our accomplishments and focus on our environmental efforts

through the release of our annual Environmental Performance Report

and other Environment Week activities.

We have a collective responsibility as Newfoundlanders and Labradorians to

conduct ourselves in an environmentally sustainable manner and to do all we can

to take care of the resources and environment entrusted to us. For Hydro, and

everyone who works here, Environment Week is a celebration; yet the remaining

51 weeks of the year are equally important in terms of our environmental

commitment and responsibilities.

Over the past year, we have spent considerable time refocusing the organization

and its goals to closely align with our expanded mandate from our shareholder.

While many of those goals focus on specific aspects of our business, one goal

intersects and impacts our entire organization:

To Be an Environmental Leader.

As a company and a member of the community we have a belief and a

responsibility to protect the environment we live and work in. We will

strengthen our commitment to protecting the environment and will focus on

reducing emissions from our power generation activities. Our Environmental

Management System and ISO 14001 certification are key components of this

commitment and they will continue to be the cornerstone of our environmental

work.

In pursuing new business opportunities, we are looking to clean, renewable

sources of energy to meet our domestic and export requirements. For example, we

are closely examining wind energy to assess how it can offset some of the

thermal generation requirements of the Holyrood Thermal Generating Station. A

request for proposals for the provision of 25 MW of cost-effective, wind energy

for the island is currently in progress and will conclude late in 2006.

Increasing wind generation will increase our renewable energy capacity and

potentially help reduce the requirement for fuel at our Holyrood plant and

reduce associated emissions. But even before that happens, we are taking

important steps to reduce sulphur emissions. In 2005, Hydro’s Board of

Directors approved the purchase of lower sulphur fuel, moving to one per cent

sulphur content instead of the current two per cent. This switch will be

completed mid-2006 and will reduce sulphur emissions by 50 per cent and

particulate emissions by 40 per cent. It is one important step to ensure

cleaner air for our neighbours near the Holyrood plant.

We have also been tasked to lead the development of the lower Churchill

resource. The capacity of the lower Churchill River to provide clean, renewable

hydro electricity is tremendous. The requirement across Canada and throughout

the United States for clean energy is an important factor in our current

efforts.

We know we are doing important environmental work, and in 2005, those efforts

were recognized externally as well. Hydro received several commendations for

its Granite Canal Hydroelectric Development including the 2005 Outstanding

Stewardship of America’s Rivers Awards from the National Hydropower

Association. The company was recognized for its Granite Canal Hydroelectric

Development that balances electricity production with the protection of local

fish species and their habitat. The facility also received the Ecologo™

Certification, which acknowledges that the electricity generated is renewable

and has a low environmental impact. As well, Granite Canal Providing Fish

Habitat and Renewable Generation was a feature article of the November 2005

issue of Hydro Review, the magazine of the North American hydroelectric

industry.

I invite you to explore the various sections of this report to learn more about

our community partnerships, how we work to preserve sensitive habitats and how

we operate the fourth largest utility in Canada to have the least environmental

impacts possible. Led by the outstanding efforts of our Environmental Services

Department, and guided by our Environmental Management Systems, we will

continue to improve our operations as we move forward with our expanded

mandate.

Ed Martin

President and CEO

|

-

In 2005, Hydro restructured its operations and goals to closely align with its

expanded mandate from the Government of Newfoundland and Labrador. While many

of those goals focus on specific aspects of our business, one goal intersects

and impacts the entire organization:

To Be an Environmental Leader.

As a company and a member of the community we have a belief and a

responsibility to protect the environment we live and work in. We will

strengthen our commitment to protecting the environment and will focus on

reducing emissions from our power generation activities. Our Environmental

Management System and ISO 14001 certification are key components of this

commitment and they will continue to be the cornerstone of our environmental

work.

-

Hydro received several commendations for its Granite Canal Hydroelectric

Development including the 2005 Outstanding Stewardship of America’s Rivers

Awards from the National Hydropower Association. The company was recognized for

its Granite Canal Hydroelectric Development that balances electricity

production with the protection of local fish species and their habitat. The

facility also received the Ecologo™ Certification, which acknowledges that the

electricity generated is renewable and has a low environmental impact.

-

In 2005, Hydro’s Board of Directors approved the purchase of lower sulphur

fuel, moving to one per cent sulphur content instead of the current two per

cent. This switch will be completed mid-2006 and will reduce sulphur emissions

by 50 per cent and particulate emissions by 40 per cent.

-

A Request for Proposals (RFP) was issued in 2005 for 25 MW of wind generation.

The RFP is in keeping with Hydro’s mandate to seek cleaner, renewable

alternatives to thermal generation. Proposals are due on August 31, 2006, and

will be evaluated in late 2006.

-

2005 marked the first full year of production at the Ramea Wind-Diesel

Demonstration Project. In accordance with the power purchase agreement with

Frontier Power Systems, wind energy offset approximately 10 per cent of the

energy requirements that otherwise would have been produced by diesel in 2005.

-

Stack emission testing was performed on the three generating units at the

Holyrood Thermal Generating Station during April 2005. The tests monitor total

particulate, particulate particle size, metals, sulphates, sulphur dioxide (SO2

nitrogen oxide (NOx), carbon monoxide (CO) and

carbon dioxide (CO2) in the exhaust-gas. The

results also provide data on our initiatives to improve overall unit

performance and efficiency.

-

The Hydrowise School Pilot Program was launched in 2005 at Bay D’Espoir

Academy. Aimed at Grade 2 and 3 students, the program helps to educate children

and their parents about ways they can conserve energy and make their homes more

energy efficient. Results showed that 92% of parents surveyed said their

households learned energy saving tips and continue to use them.

-

In 2005, Hydro undertook an assessment of rare plants associated with sections

of distribution lines to Boat Harbour and Cape Norman, on the Province’s Great

Northern Peninsula, to determine the best possible location for new poles in

relation to the plant species.

-

In 2005, as part of the Rencontre East interconnection project, Hydro conducted

wildlife surveys resulting in the first confirmed sighting on the Bay Du Nord

system of a breeding pair of Harlequin Ducks.

-

Hydro participated in the Labrador Woodland Recovery Team continued with the

development of a Recovery Strategy. This document identifies recovery

strategies deemed necessary to protect and recover sedentary woodland caribou

in Labrador.

-

In 2005, Hydro was proud to continue its support of the Conservation Corps of

Newfoundland and Labrador through sponsorship of the Coast of Bays Arts and

Exploration Centre Green Team. This group focused on the creation of a trail

way surrounding the Coast of Bays Arts and Exploration Centre in the Bay

D’Espoir area.

-

MUN Botanical Garden held a Junior Naturalists’ Camp for children of Hydro

employees in July 2005. The camp was offered as part of Hydro’s partnership

with the Garden for the establishment of natural vegetation along the banks of

the Granite Canal Fish Habitat Compensation Facility.

-

In 2005, Environmental Site Assessments were carried out on sites throughout

Hydro’s system including CF(L)Co. Eleven Phase I ESAs were completed; nine

Phase II ESAs, complete with Risk-Based Corrective Actions (RBCAs); and 10

RBCAs were undertaken based on Phase II ESAs completed during previous years.

|

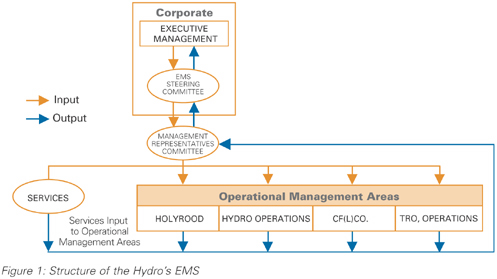

Hydro’s Environmental Management System (EMS) allows for the management of our

environmental affairs and is applied to all activities, products and services

that can have impact on the environment. Overseeing the operational management

of the EMS is the Management Representatives Committee (MR Committee) with

representatives from each of the Management Areas (MA)within the EMS. The MR

Committee provides advice to a senior EMS Steering Committee which oversees the

EMS on a corporate level.

The MR Committee meets on a regular basis and provides the following:

-

an open exchange of information, approaches and ideas related to EMS

development and implementation;

-

maintenance of consistent application of Corporate EMS procedures, and

direction from the EMS Steering Committee;

-

a single point of communication between the EMS Steering Committee and top

management in each MA; and

-

a forum for training and mentoring newly appointed Management Representatives.

The MR Committee keeps a global watch over the progress and development of

Environmental Management Programs within each MA to ensure the overall approach

and philosophy of Hydro’s commitment to environmental responsibility and

responsiveness is upheld every day. The successful completion of the

registration process for ISO 14001 across the Corporation is reflective of the

efforts of Hydro’s MR Committee.

In 2005, the MR Committee included: David Kiell, Corporate MA; Louis Barnes,

Hydro Operations MA; Cindy Hayes, CF(L)Co MA; Rod Healey, Services MA; Wayne

Rice, Holyrood MA; and Paul Smith, Transmission and Rural Operations MA.

While everyone at Hydro plays an important role in ensuring the organization

meets its environmental commitments, the Environmental Services Department has

the lead responsibility for areas of environmental reporting, environmental

impact and site assessment, environmental auditing, identifying appropriate

environmental standards, and tracking environmental issues. As well, the

Department provides advice and service to all divisions in Hydro to assist them

with their legislative compliance responsibilities.

|

In 2005, with a renewed mandate and refocused organization, Hydro set strategic

goals to guide its business into the future. One of those goals highlights the

organization’s ongoing and continued commitment to environmental

responsibility.

Goal: To Be an Environmental Leader

As a company and a member of the community we have a belief and a

responsibility to protect the environment we live and work in. We will

strengthen our commitment to protecting the environment and will focus on

reducing emissions from our power generation activities. Our Environmental

Management System and ISO 14001 certification are key components of this

commitment and they will continue to be the cornerstone of our environmental

work.

Our structured and consistent management approach to dealing with environmental

issues facing Hydro has proven to be successful, and we have committed to

continue to build on the success achieved in 2005.

Our Environmental Management Systems (EMS) provide us with a solid framework

for environmental management and continual improvement. We are committed to

managing our operations to reduce our environmental impact, while balancing our

mandate to provide our customers with safe, reliable, least-cost power. All

Hydro divisions have been ISO 14001 certified since 2004, and this gives added

assurance to all our stakeholders of continued environmental excellence.

The six designated management areas (Figure 1) within Hydro manage their

environmental aspects through EMS’s consistent with ISO 14001. Each EMS is

certified and registered by a third party,

Quality Management Institute (QMI).

In 2005, Hydro continued to show improvements on our environmental Key

Performance Indicators, electronic EMS documentation and EMS surveillance

audits. General accomplishments resulting from the Environmental Management

Programs (EMP) in each of the Management Areas in 2005 are detailed in this

section.

The Corporate Management Area consists of the leadership team and a committee

of managers with responsibilities for facilities and operations with

environmental aspects. The goal of this Management Area is to co-ordinate the

development and maintenance of the overall EMS for Hydro and to identify

environmental aspects appropriate to the leadership team’s activities and

responsibilities. Although the operational and services EMS are managed

independently, a common and consistent Corporate Environmental Policy and

Guiding Principles sets the standard. Periodic reviews of activities and issues

are conducted to ensure consistency with corporate standards.

Two significant environmental aspects were identified in the Corporate

Management Area EMS review in 2005. These were:

-

communication of Hydro’s environmental policy and performance to relevant

stakeholders; and,

-

management of emerging and critical environmental issues.

Objectives, targets and programs were identified and pursued related to each of

these aspects. Some of the accomplishments included:

-

undertaking a process review of the Environmental Performance Report format and

production of the annual report in the format chosen;

-

production of a draft fact sheet related to the management of treated wood;

-

advertising Hydro’s environmental commitment and activities in external

publications;

-

preparation of the environmental section of Hydro’s Intranet site;

-

production of environmental articles in the Outlet, Hydro’s internal

newsletter; and

-

observance of Environment Week at Hydro Place, in St. John's.

As well, in 2005, Hydro’s Leadership Team and Board of Directors reviewed

options for managing air emission issues associated with the 490 MW Holyrood

Thermal Generating Station and approved a major initiative to improve the

quality of air emissions by reducing the specified maximum sulphur content of

the bunker “C” fuel burned at this facility from two per cent to one per cent.

This change is projected to reduce emissions of sulphur dioxide by 50 per cent

and emissions of particulate by 40 per cent. Also in 2005, Hydro tracked

federal government initiatives relating to emissions of greenhouse gases and

evaluated strategies for ensuring compliance.

Currently there are four groups within the Services Management Area that have

environmental aspects identified. These groups include: Systems Operations and

Customer Services, Engineering, Supply Chain Management and Environmental

Services.

In 2005, results included:

-

negotiation and finalization of the Diesel Generating Station Certificate of

Approval with the Department of Environment and Conservation;

-

2005 marked the first full year of production at the Ramea Wind-Diesel

Demonstration Project. Through the power purchase agreement with Frontier Power

Systems, Hydro purchased 418,000 kilowatt hours (kWh) of energy, offsetting

about 10 per cent of Ramea’s requirements in 2005 that would otherwise have

been supplied by diesel generation;

-

ongoing progress on a program managed by the TRO Engineering Department to

improve management of sulphur hexafluoride (SF6

a gas with significant greenhouse gas (GHG) potential, through education and

development of handling procedures designed to reduce the potential for

releases to the environment;

-

ongoing management of the impact of the Granite Canal Hydroelectric Generating

Station’s operations on fish habitat. This involves the development and

implementation of controls and procedures to coordinate the operation of the

generation facilities with the Fish Habitat Compensation Facility constructed

as part of this development; and

-

in 2005, Environmental Site Assessments were carried out on sites throughout

Hydro’s system including CF(L)Co. Eleven Phase I site assessments were

completed, nine Phase II ESA, complete with Risk-Based Corrective Action

(RBCA); and 10 RBCAs were undertaken based on Phase II ESAs completed during

previous years.

Thermal

The Holyrood Thermal Generating Station is a 490 MW plant located in Holyrood,

Conception Bay South. Holyrood’s EMS was initially registered in January 1999,

and obtained re-registrations in 2002 and 2005.

In 2005, Holyrood made progress on 13 EMPs, resulting in:

-

an improvement in efficiency of the conversion of fuel energy and associated

reduction in selected emissions intensities;

-

inspection and remediation of fuel containment equipment;

-

completion of a study on the control of regeneration wastes;

-

advancement of an emissions reduction strategy and approval to reduce fuel

sulfur content from two per cent to one per cent;

-

continued removal of PCB waste and asbestos from the plant; and

-

continued recycling of scrap metal.

Hydro Operations

The Bay D’Espoir Management Area consists of seven existing generating stations

on the island with an installed capacity of 604 MW.

In 2005, some of the results included:

-

as a way to minimize the risk associated with undergroun fuel storage systems,

three underground fuel systems were removed and replaced with above ground

double-walled fuel systems;

-

implementation of a new standard operating procedure for pressure testing of

fuel piping systems;

-

switch to environmentally friendly lubricants for Unit 7 at the Bay D’Espoir

Generating Station;

-

development and delivery of an Environmental Awareness Program to Hydro

generation employees; and a study of energy consumption at the Bay D’Espoir

site resulted in new procedures for conservation.

Churchill Falls

The Churchill Falls Hydroelectric Generating Station has an installed capacity

of 5,428 MW. Associated with this development is approximately 1,200 km of

high-voltage transmission lines, an airport and the Town of Churchill Falls.

Environmental aspects of these facilities are included in the EMS. The

environmental aspects of the decommissioned Twin Falls Hydroelectric Station

are also managed through CF(L)Co’s EMS. The EMS was registered in 2000 and

re-registered in 2003.

Some of the results of the 2005 EMPs were:

-

continued use of environmentally-friendly wicket gate grease and transformer

oil, with seven of 11 turbines and six of 11 transformers converted to

environmentally-friendly products to date;

-

a monitoring program to ensure ability to prioritize maintenance for turbine

units that experienced the highest oil losses. One turbine unit is repaired per

year;

-

conversion of two drainage sumps in the powerhouse into oil water separators;

-

training was completed by employees in the areas of environmental emergency

response planning, basic oil spill response, environmental awareness training,

and training by line crews related to the environmental protection plan for

transmission and distribution line maintenance;

-

a wind-blown debris fence installed at the town and plant landfill was

constructed 7.6 meters high and 120 meters long; and

-

a river oil response building was constructed near the tailrace.

Transmission and Rural Operations

The Transmission and Rural Operations (TRO) Division consists of three regions

that manage 23 rural, isolated diesel generating plants (30.2 MW), three gas

turbine plants (125 MW), and approximately 7,350 km of transmission and

distribution lines and associated switching stations. The three regions share a

common EMS. In 2005, Network Services was added to the EMS.

In 2005, significant accomplishments included:

-

updates to the five-year plan for improvements to prevent potential

environmental impacts from fuel storage systems;

-

updates to the five-year test plan for the reduction of PCBs to indicate

equipment to be tested;

-

a protocol for identification, removal and disposal of PCB contaminated

lighting ballasts;

-

continuation of a study for alternate forms of applications to reduce the use

of herbicides for vegetation control;

-

completed information collection related to environmental sensitivities for new

transmission and distribution lines in TRO Central, Northern and Labrador and

-

utilization of a software package to update and track treated-wood material removed from

service, recycled, reused, stored or disposed.

|

The Holyrood Thermal Generating Station’s wastewater treatment plant treats the

wastewater resulting from the combustion of fuel and run-off from the solid

waste landfill. Components of the wastewater from the plant are measured and

compared to regulatory limits. Once all aspects of the wastewater meet

provincial regulatory requirements, the wastewater is released into the

environment. In 2005, 6.29 million litres of wastewater were treated and

discharged, which is a slight decrease from the 6.74 million litres of

wastewater processed in 2004.

Hydro relies on both hydroelectric and thermal generation to meet customer

needs for electricity. The operation of the Holyrood plant is highly dependent

on the availability of water in our hydroelectric reservoirs. Water levels in

our reservoirs vary annually with the amount of precipitation and runoff. When

water levels increase in the reservoirs, the demand on thermal generation

decreases, as does associated air emissions. The opposite is also true.

Total emissions were lower in 2005 than 2004 as a result of a greater

percentage of hydroelectric as opposed to thermal generation enabled by

increased inflows in the reservoirs. Concentrations per unit of fossil

generation increased on account of lower average unit output levels. System

emission ratios, with the exception of NOx,

decreased due to greater hydroelectric production and greater purchases of

energy. The NOx emission ratio did not decline

because of a significant increase in the calculated NOx

emissions from small diesel plants in isolated areas in the province.

|

|

|

|

|

|

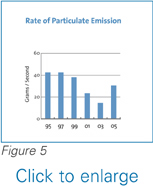

As part of an agreement with the Department of Environment and Conservation,

Hydro conducts stack testing for the rate of particulate emissions at the

Holyrood plant biannually. Testing conducted in April 2005 indicated the

emission rate for particulate was 30.7 grams per second (g/s). This is the

average emission rate for all three units from stack emission testing

conducted. This is considerably higher than the average emission rate

identified in 2003 (10.6 g/s) and is more comparable to average particulate

emission rates recorded in 2001 (23.5 g/s) and 1999 (38.1 g/s). The increase in

particulate emission rate compared with 2003 is partly

|

|

|

attributable to testing of a fuel additive on one of the generating units

during the winter of 2004/2005 that may have added to the particulate

emissions. However, particulate emissions from all three units were higher in

2005 than in 2003.

|

In 2005, Hydro made a decision to burn cleaner fuel at the Holyrood plant. The

maximum fuel sulphur content will be reduced from two per cent to one per cent

by mid-2006. The decision will significantly improve on air emissions from the

plant. The cleaner fuel is expected to decrease the annual sulphur dioxide

emissions by 50 per cent and reduce particulate emissions by 40 per cent. The

cost for cleaner fuel will be marginally higher, but Hydro believes it is the

right investment for the plant, stakeholders in surrounding communities, and

the environment and tom facilitate compliance with regulatory requirements.

Stack emission testing, conducted every two years, was performed on the three

generating units at Holyrood during April 2005. The tests monitor total

particulate, particulate particle size, metals, sulphates, SO2,

NOx, CO and CO2

in the exhaust-gas.

Test results are reported to the Department of Environment and Conservation to

satisfy an existing agreement, and are used for on-site evaluation, the annual

report on air emissions, exhaust-gas modeling, and reporting to Environment

Canada through the

National Pollutant Release Inventory and Greenhouse

Gas Emissions Reporting. The results also provide data on our initiatives to

improve overall unit performance and efficiency.

|

Polychlorinated Biphenyls (PCB) is the most important waste management issue in

the electric utility industry. This substance was commonly used in electrical

equipment prior to the late 1970s, when PCB production was banned. The effect

of this ban on Hydro and many other utilities was two-fold. The amount of PCB

in service declined as new PCB-free equipment was installed and inventories of

PCB-contaminated wastes increased as older equipment was retired.

During the 1980s and 1990s, Hydro implemented significant initiatives to reduce

risks associated with in-service equipment containing PCB. This included

removal from service or decontamination of all transformers which had been

manufactured with high concentrations of PCB. As well, all transformers filled

with large volumes of PCB-contaminated oil were decontaminated.

Some low risk older equipment such as florescent light ballasts which contain

small amounts of PCB are managed to prevent any releases into the environment,

and will remain in-service for their life. A portion of older distribution

equipment, currently in service, contains oil that is contaminated with low

level PCB. Hydro’s policy is to test this equipment for PCB contamination

during emergency and planned maintenance, and collect all PCB contaminants for

proper disposal.

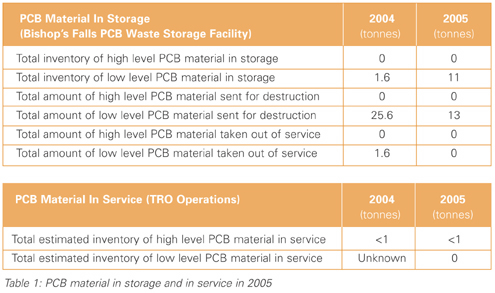

In 2005, 11 tonnes of low-level PCB material was placed in storage at our

Bishop’s Falls PCB waste storage facility. Approximately 13 tonnes of low-level

PCB material was removed from storage during 2005 and destroyed. Therefore, as

of December 31, 2005, there was no low or high- level PCB material in storage

It is recognized that some older equipment such as capacitors and fluorescent

light ballasts, which may contain high levels of PCB, remains in service. It is

estimated that there is less than one tonne of PCB contained in this equipment.

A portion of the older distribution transformers in service throughout the

system contain oil that is contaminated with PCB to a level greater than 50

ppm. Hydro has therefore initiated a program to reduce the amount of PCB

contaminated equipment in service. The multi-year program involves the

identification, testing, and removal from service or refurbishment of all

electrical equipment with a PCB level greater than 50 ppm.

Table 2 provides an inventory of PCB material in storage and in service at

Churchill Falls facilities as of December 31, 2005. At present, the total

amount of low and high-level PCB material in storage in the Churchill Falls PCB

waste storage facility is less than 1 tonne. No PCB material was sent for

destruction in 2005. PCB material known to be in service are ballasts and

capacitors; however, there is no inventory completed of this electrical

equipment to date.

Lubricating Oil

Hydro currently has a waste oil management system for handling and disposing of

various types of used oil. In the past, however, records on the amount and type

of oil being recycled were not always kept. Hydro has made significant progress

over the last couple of years in this area and now reports on an annual basis

the amount of used lubricating oil generated and new oil purchased for our

diesel generating stations to the Department of Environment and Conservation

(DOEC). In 2005, approximately 46,000 litres of used lubricating oil was

collected from our diesel stations for recycling.

In 2005, at CF(L)Co, approximately 34,000 litres of used lubricating oil was

collected and properly disposed of by a government-certified, third-party waste

oil contractor for heat recovery.

Insulating Oil

At Hydro’s central maintenance facility in Bishop’s Falls, approximately 42,000

litres of insulating oil was reused. Approximately 2,000 litres of this

insulating oil was reused following processing or cleaning by internal forces,

while 40,000 litres was reused following processing or cleaning by a

third-party contractor.

At CF(L)Co in 2005, approximately 192,000 litres of insulating oil was removed

from underground transformers and replaced with an environmentally-friendly

insulating oil.

Scrap Metal

During 2005, Hydro decommissioned 520 distribution transformers, all of which

were sold to a transformer manufacturer for reuse. In addition, scrap

aluminum/steel tower components and miscellaneous scrap were auctioned at

Hydro’s central maintenance facility in Bishop’s Falls for recycling.

During 2005, CF(L)Co, as part of the scrap metal recovery management program,

collected and recycled approximately 773 tonnes of scrap metal from areas that

were used during original construction of the Churchill Falls project.

Treated Wood

Hydro, as part of it transmission line network, manages approximately 26,000

poles of varying age. Wooden poles have an economic lifespan of about 40 years

and an in-service lifespan of 50 years. With proper management, maintenance and

refurbishment, the life can be extended by 10 years or more. In Hydro’s

transmission system, just over one third of all poles are 30 years or older and

are nearing the end of their useful life. Core samples taken from some poles in

1998 indicated that the preservation retention level was not adequate. As a

result, Hydro initiated a wood pole line management program in 2003 and it is

expected to continue as a long-term asset management and life extension

program. In 2005, Hydro treated 2,700 poles with boron rods. In 2005, 2,364

treated wood poles were removed from service; 47 were removed to landfills,

while 2,317 were recycled.

Boiler Ash

During 2005, all fuel ash produced at the Holyrood Thermal Generating Station

was disposed of in an on-site, controlled solid waste landfill. The amount of

total ash produced and disposed of at the landfill in 2005 was 420 tonnes.

Other

In 2005, CF(L)Co sent five pallets of wet cell batteries for recycling,

totaling approximately 9,100 kilograms.

|

The very nature of the work involved to generate and transmit electricity

requires handling and use of a variety of potential environmental contaminants

such as fuel oils, lubricating oils and chemicals. In 2005, Hydro used

approximately 15 million litres of diesel fuel and 340 million litres of No. 6

fuel oil to generate electricity. As part of standard operating procedures,

Hydro strives to reduce the potential for leaks and spills. However, incidents

can occur and are most often the result of equipment failure, unanticipated

hazards, and occasionally, human error.

Being prepared for such an incident is critical to mounting a quick and

effective response to minimize impacts on people and the environment. Hydro has

developed Environmental Emergency Response Plans (EERP) to quickly, effectively

and safely deal with such incidents. Within Hydro, all personnel who handle or

work around petroleum products receive training related to the EERP and, when

applicable, specific operating procedures have been developed to facilitate the

safe handling of the products used.

Hydro had three reportable spill and leak incidents in 2005. None of the spills

were of a significant volume or entered a water body. The approximate volume

for all reportable spills was 160 litres, down from 523 litres in 2004. All

reportable spills involved petroleum products or its derivatives, with 40 per

cent being non-PCB-contaminated transformer oil and 60 per cent being glycol.

It should be noted that one of the reportable incidents was a leak of unknown

quantity, which was reported at one of our standby gas turbine generating

facilities.

CF(L)Co had five reportable spills in 2005, two of which entered water bodies.

The total volume of oil was 305 litres of petroleum type products, an unknown

quantity of transformer oil from the switchyard, and 100 litres of glycol from

the town arena. The unknown quantity of transformer oil was released from the

switchyard due to a water main break that intercepted oily soil and resulted in

oily water runoff from the yard.

The total volume of liquid reportable spills cleaned up is estimated. The

estimations are based on 100 per cent recovery of spills or leaks on soil. In

all spills from our distribution system, Hydro recovered contaminated soil and

verified, through sampling, that the level remaining was within acceptable

levels.

|

In 2000, Hydro implemented an Environmental Site Assessment (ESA) program for

all properties it owns or operates. The process followed is illustrated in

Figure 6.

The objectives of the ESA program are to:

-

evaluate the potential for environmental contamination;

-

undertake sampling to characterize and delineate any contamination;

-

assess the potential risks and liabilities associated with any contamination

identified;

-

identify sites requiring monitoring or remediation; and

-

develop and implement remediation programs when necessary.

Since the inception of the ESA program in 2000, the sites of all rural isolated

generating stations have been assessed at least to a Phase I level. These are

the sites with the highest environmental risk based on the throughput of

potential contaminants. The program will now focus on facilities with less

hydrocarbon storage capacity, and therefore, potential risk such as terminal

stations, material storage yards and line depots.

In 2005, throughout Hydro’s system, 11 Phase I ESAs were completed; 9 Phase II

ESAs, complete with Risk-Based Corrective Action (RBCA); and 10 RBCA were

undertaken based on Phase II ESAs completed during previous years. This

included ESA work undertaken at CF(L)Co.

Table 3 shows the ESA work that was accomplished in 2005 and future plans, if

any, for the site.

|

|

|

In 2005, Hydro conducted an assessment of rare plants associated with sections

of distribution lines to Boat Harbour and Cape Norman, on the province’s Great

Northern Peninsula. Work involved the installation of a number of mid-span

poles and the replacement of older creosote poles that had deteriorated on

these lines. All work was near the main road, but also traversed very sensitive

limestone barrens habitat known to support species identified as rare or

endangered for the province and under the provincial Species at Risk Act. Of

particular concern was the presence of Fernald’s Braya (S2 Threatened) and

Barrens Willow (S1 Endangered) along the line route, near some structures, and

along the main road. Also of concern was the presence of a Fernald’s Braya

Study Plot established by Memorial University closer to the line to Cape

Norman.

As part of the assessment, the best possible location for the new poles was

chosen in relation to the plant species. All trails, travel routes and work

locations were identified and appropriately marked with a particular color. The

location of rare plants were also marked, but with a different color. This

allowed the line crew to easily distinguish the approved travel route and the

location of sensitive plant species. Once all trails and routes were marked,

they were then assessed for rare plant species. A local plant expert was hired

to complete the assessment and to report the results of the assessment to

Hydro.

In 2006, Hydro will be compiling a single report on rare plants associated with

power lines in the Great Northern Peninsula. This report will incorporate five

years of survey data collected on distribution lines at Trout River, Point

Riche and Barbace Point at Port Aux Choix National Historic Site, Cooks Harbour

to the Big Brook Junction, Cooks Harbour to Wild Bight and Boat Harbour, and

Wild Bight to Cape Norman. This information will then be incorporated into an

Environmental Protection Plan for use by our Northern Region line crews.

The Granite Canal hydroelectric development is located in south-central

Newfoundland within Hydro’s existing Bay D’Espoir System. Granite Canal began

production in July 2003 and has a capacity of 40 MW.

The Granite Canal project brought together a team of engineers, ecologists,

hydrologists, biologists and managers to develop an innovative design that

would meet the requirements of the local fish populations and satisfy federal

and provincial regulations. In addition, the team considered how the variable

conditions naturally found within fish habitat could be integrated into the

project’s engineering and construction requirements. The result was the Fish

Habitat Compensation Facility (FHCF) that provided 45,000m2

of spawning and rearing habitat for tens of thousands of ouananiche

(land-locked Atlantic Salmon) and brook trout that were displaced from the

existing waterway below the Granite Canal discharge when the water in Granite

Canal was diverted.

Initial results from FHCF monitoring programs and research activities indicate

the design has been successful, with the facility being used by large numbers

of fish. In 2005, the FHCF remained at a very high level of production for both

ouananiche and brook trout. Stock values for ouananiche have been estimated at

117 grams/100m2 and 3.7 grams/100m2 for brook

trout. In addition, spawning surveys recorded approximately 850 redds. As part

of an agreement with the Department of Fisheries and Oceans, Hydro has

committed to monitoring production in the FHCF until 2010.

In 2005, as part of the Rencontre East interconnection project, Hydro conducted

in situ wildlife surveys. One of the results was the discovery of a breeding

pair of Harlequin Ducks on the Bay Du Nord River. The Harlequin Duck was

designated as vulnerable in 2002 under the provincial Species at Risk Act. This

is the first confirmed sighting of this species on the Bay Du Nord River

system. A summary report of these findings was provided to the provincial DOEC.

In 2005, Hydro, as part of long-term agreements with them Department of

Fisheries and Oceans, released approximately 155 MCM (million cubic metres) of

water at its fisheries compensation facilities. The water releases at White

Bear River, Grey River, Granite Canal, Upper Salmon and Hind’s Lake were

performed at critical times through the year for habitat protection and fish

migration. In comparison, the amount of thermal production required to offset

the amount of water released was 45.5 GWh. When the thermal conversion rate and

average cost of fuel are considered, the equivalent value of the water released

at all fisheries compensation facilities totaled approximately $2.7 million.

CF(L)Co has existing transmission, generation and control facilities within the

range of both the Lac Joseph and Red Wine Mountains caribou herds. The proposed

Lower Churchill River Hydroelectric Development also falls within the range of

these sedentary woodland caribou herds which were designated as threatened in

2001. The Committee on the Status of Endangered Wildlife in Canada designated

the herds as threatened under the federal Species at Risk Act. DOECm also

designated these herds as threatened under the provincial Species at Risk Act

in July 2002.

To demonstrate our commitment to addressing species at risk issues, Hydro has a

representative participating on the Labrador Woodland Recovery Team. In 2005,

the recovery team continued with the development of a Recovery Strategy, which

is a document that identifies recovery strategies deemed necessary to protect

and recover sedentary woodland caribou in Labrador. The Recovery Team will be

implementing various aspects of the plan as departmental budgets allow.

|

Newfoundland and Labrador has a world-class wind resource. Currently, the

island’s electrical system is isolated from the North American grid and has an

existing generating capacity of 1,919 MW provided by approximately 65 per cent

hydroelectric and 35 per cent fossil fuel generation. Hydro, as part of its

2005 mandate and portfolio expansion, is looking at wind as a cleaner renewable

alternative to oil-fired energy. In December 2005, Hydro issued a Request for

Proposals (RFP) for 25 MW of wind generation. Replies to the RFP will be

reviewed and evaluated during the fall of 2006. If an acceptable agreement with

a proponent can be reached, the benefit will be two-fold: clean, cost-effective

energy from wind and potential fuel displacement from oil-fired generation.

Ramea

Hydro continued purchasing wind generation at one of its rural isolated diesel

generating sites in 2005. For over a year, as part of a pilot project, Hydro

has been purchasing power from the province’s first wind-diesel demonstration

project in Ramea, an isolated community off the southwest coast of the island.

The focus for the project is the development of medium penetration wind-diesel

systems that combine the use of diesel powered generators with wind turbines.

Six, 65 kilowatt (KW) wind turbines totalling 390 KW are installed. Current

production estimates show that Hydro can offset approximately 200,000 litres of

diesel fuel annually with wind generation at Ramea. In 2005, the first full

year of operation, the project produced 418,000 kilowatt hours and provided 10

per cent of Ramea’s energy needs.

This project is being supported by the Government of Canada’s Technology Early

Actions Measures (TEAM) Program. TEAM is an interdepartmental technology

investment program established under the federal government’s Climate Change

Action Plan. TEAM financing and federal technical support has enabled major

demonstrations of potential greenhouse gas (GHG) reducing technologies in

communities across Canada. Information about Ramea Wind-Diesel Demonstration

Project and video can be found on the

Technology Early Action Measures (TEAM)

link.

St. Brendan's

In 2005, Hydro signed a power purchase agreement with a private developer who

wishes to build a wind farm at St. Brendan’s, another rural isolated diesel

generating site on the island’s northeast coast. A decision by the developer to

move forward is still pending.

|

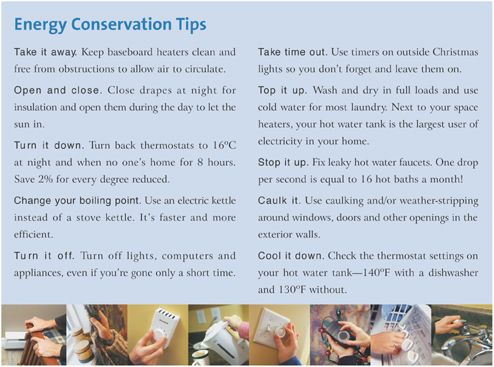

In 2003, Hydro launched its conservation education program – Hydrowise. The

program is an education initiative aimed at provoking interest in energy

conservation and assisting residents of this province to better manage their

energy usage. This initiative reflects our continued commitment to our

customers and all residents in conserving energy and ultimately managing our

resources. Hydrowise will continue to educate and inform customers over time in

a continuous and consistent manner.

Conservation is not a one-time effort; it is something that has to be

integrated into everyone’s way of thinking. We are committed to providing

customers with the information they need to make wise decisions and take action

to better manage their energy usage.

In 2005, Hydro went back to school. The company launched the Hydrowise School

Pilot Program aimed at educating Grade 2 and 3 students about conservation. By

talking to children, we are also educating their families on the practices that

can reduce their energy usage. This fun and interactive program was piloted at

Bay D’Espoir Academy in the fall. Integrated into the class curriculum,

teachers were given a kit of resources to lead their classes through a series

of Secret Missions designed to take them from Agents in Training to Hydrowise

Special Agents. Feedback from the pilot was overwhelmingly positive and plans

are underway to expand the program to other schools and grades in the province.

|

|

|

Hydro is committed to community partnerships with other agencies and

organizations to achieve common environmental objectives. Through shared human

and financial resources we can work together to compile a body of knowledge and

experience that can assist all partners in environmental decision-making.

Hydro partnered with the

MUN Botanical Garden, continuing its commitment to

environmental responsibility in a new and innovative way. The partnership was

developed as a result of Hydro’s efforts to reconstruct a fish habitat that

would compensate for the habitat lost through the building of the Granite Canal

Hydroelectric development.MUN Botanical Garden was able to provide Hydro with

native plants, not available at local plant nurseries, by collecting seeds

and/or cuttings from the area. MUN Botanical Garden then propagated these seeds

and cuttings and assisted with the planting and monitoring of the growth along

the riverbanks of the compensation facility. The propagation of particular

local species from seeds, cutlings and culture to provide the number of plants

required has been a challenge and has resulted in delays in the original

planting schedule. Approximately 30,000 plants and seedlings were planted by

hand at the Granite Canal Fish Habitat Compensation Facility in 2005. Up to

70,000 more will be planted as part of the program in 2006.

Out of our partnership with the MUN Botanical Garden grew a summer camp for

children of Hydro employees held in July 2005. The children got an opportunity

to experience first hand all the Botanical Garden had to offer. From various

habitats such as boreal forests and wetlands, to animals like the snowshoe

hare, green frogs, butterflies and insects, the children learned and

experienced a wide variety during the week-long camp.

The children also got to hear from the Green Team about the importance of

conservation, and they even became Green Team Police tasked with helping to

bust environmental abusers. A visit from a Water Quality Officer, crafts,

movies, and journal writing rounded out their exploration of nature and all the

critters and plants that live at the Botanical Garden.

Hydro has a long-standing relationship with the

Conservation Corps of Newfoundland and Labrador.

In 2005, Hydro sponsored the Coast of Bays Arts and Exploration Centre Green

Team, which focused on the creation of a trail way surrounding the Coast of

Bays Arts and Exploration Centre in the Bay D’Espoir area. Components of the

trail development included conducting an inventory of the surrounding flora and

fauna, designing interpretive signage to explain the regenerative process that

occurred in the area of the trail and performing tours along the trail to

highlight the plants, animals, history and culture of the area. The team of

four also held five Environmental Awareness Days for community groups ranging

from children to seniors.

In 2005, Hydro continued its partnership with the Conservation Corps to support

the Climate Change Education Centre

(CCEC). The CCEC develops and

delivers innovative education and outreach programs to educate the public on

climate change and influence how they respond to this environmental concern.

|

|